面向读者:供应链管理从业者 | 供应链管理系统的IT从业者 | 供应链管理高管 | 企业IT高管 | 供应商

阅读目标:这篇文章可以帮助您宏观的快速了解大数据技术对供应链管理的影响,帮助您的企业未来在供应链环节讨论是否引入大数据技术打下一个概念基础。你不一定真的看完或者理解全文,但至少可以为大家提供一些可信的数据参考,而不是盲目毫无头绪的去“猜”大数据到底对未来的供应链管理有什么影响。

关键标签:供应链管理 | SCM | 大数据 | Big Data

概 要

大数据可以为供应商网络(Supplier Networks) 提供更好的数据准确性(Accuracy)、清晰度(Clarity)和洞察力(Insights),从而在共享的供应网络中实现更多的情境智能(Contextual Intelligence)。

Bottom Line: Big data is providing supplier networks with greater data accuracy, clarity, and insights, leading to more contextual intelligence shared across supply chains.

有前瞻目光的制造商们正在将80%或更大比例的供应网络经营活动构建在其企业外部,他们利用大数据和云计算技术来突破传统ERP系统和供应链系统的局限性。对于商业模式基于快速产品周期迭代和产品上市速度的制造商,传统的ERP/SCM系统仅仅是为了完成订单交付、发运和交易数据而设计的,这样的传统系统的扩展性极其有限,根本无法满足当下供应链管理所面临的种种挑战,已经成为企业供应链管理的瓶颈。

Forward-thinking manufacturers are orchestrating 80% or more of their supplier network activity outside their four walls, using big data and cloud-based technologies to get beyond the constraints of legacy Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) systems. For manufacturers whose business models are based on rapid product lifecycles and speed, legacy ERP systems are a bottleneck. Designed for delivering order, shipment and transactional data, these systems aren’t capable of scaling to meet the challenges supply chains face today.

如今的制造商都立足于在准确性(Accuracy)、速度(Speed)和质量(Quality)方面开展市场竞争,这一定位迫使企业的供应商网络必须具备一定程度的情景智能的能力,传统的ERP/SCM系统是无法帮助企业达成这一竞争目标的。然而当今大多数企业还没有将大数据技术引入其供应链运营当中,本文介绍的十大要素将成为企业未来供应链战略变革的重要催化剂。

Choosing to compete on accuracy, speed and quality forces supplier networks to get to a level of contextual intelligence not possible with legacy ERP and SCM systems. While many companies today haven’t yet adopted big data into their supply chain operations, these ten factors taken together will be the catalyst that get many moving on their journey.

举个小实例来说明大数据分析(BDA – Big Data Analytics)如何在准确性、速度和质量方面对供应链管理提升的作用:

亚马逊Amazon利用大数据来监控、追踪、确保其15亿库存商品准确的存放于全球200个订单履行中心(fulfilment centers)当中。亚马逊利用预测分析(Predictive Analytics)技术可以实现“预期发货(anticipatory shipping)”的情景,即,当客户打算购买一件商品的时候(注意是打算购买尚未正式下单),亚马逊就将货物提前发运(pre-ship)到离客户最近的仓储中心。这种对供应链管理的优化极大的提升了其客户的体验。

大数据变革供应链

目前,由供应链产生的数据的规模(scale)、广度(scope)和深度(depth)都在加速增长,为情景智能(contextual intelligence)驱动的供应链提供了充足的数据基础。

The scale, scope and depth of data supply chains are generating today is accelerating, providing ample data sets to drive contextual intelligence.

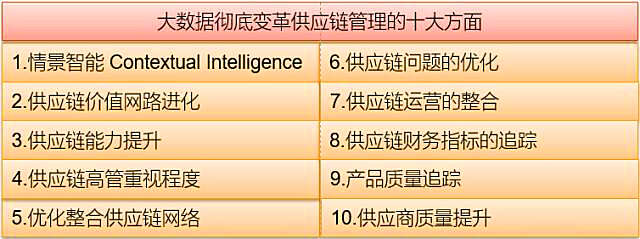

下面“图1”很有意思,它收集了整个供应链中的52种不同的数据源(包括结构化/半结构化/非结构化数据),并从大数据的三个维度(3Vs)进行了统计分析,数据量(Volume)/数据速度(Velocity)和数据多样性(Variety)。其中很明显绝大部分数据都是从企业外部产生的。有前瞻性的制造商已经开始将大数据作为更广泛供应链协作的催化剂。

The following graphic provides an overview of 52 different sources of big data that are generated in supply chains Plotting the data sources by variety, volume and velocity by the relative level of structured/unstructured data, it’s clear that the majority of supply chain data is generated outside an enterprise. Forward-thinking manufacturers are looking at big data as a catalyst for greater collaboration.

图 1:点击查看高清大图

值得注意的是,在核心交易系统范畴内,传统的ERP, SRM和CRM系统通常在企业内部的数据量(Volume)是很高的,但是这些数据放在整个52中数据源框架下只占了很小的比例,这就是为什么图1中的“核心交易系统数据”处于纵向较低的位置。如果你看右上角可以发现,高数据量和速度的非结构化数据大都是与“客户”交互的数据:社交数据、在线调研、移动位置传感设备等。

大数据分析(BDA – Big Data Analytics)技术在供应链管理领域的应用通常被称为:供应链大数据分析技术 SCM Big Data Analytics,它可以被定义为一个流程,即,将高级数据分析(Advanced Analytics)技术与供应链管理理论相结合并应用于更大的数据集合当中,这个数据集合的体量、速度和多样性需要借助于大数据技术工具来分析;同时,需要借助供应链管理专业人士的技能通过提供精准实时的商业洞察来持续感知和反馈解决SCM相关的问题。

SCM Big Data Analytics is the process of applying advanced analytics techniques in combination with SCM theory to datasets whose volume, velocity or variety require information technology tools from the Big Data technology stack; leveraging supply chain professionals with the ability to continually sense and respond to SCM relevant problems by providing accurate and timely business insights.

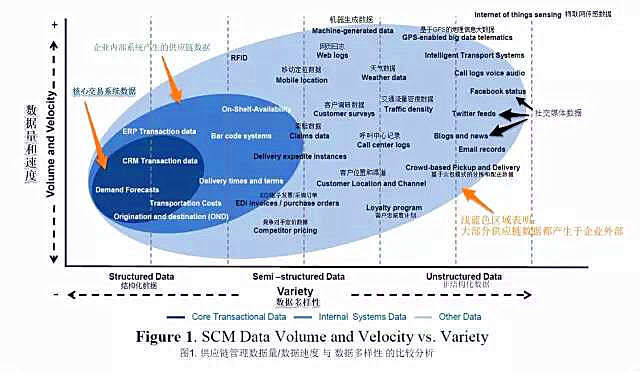

大数据驱动的供应链管理(Big Data Driven SCM) 需要首先理解供应链中的四种行为:买(buy)、卖(sell)、移动(move)和存储(store);这四种行为对应四种SCM杠杆(SCM levers):采购(procurement)、市场(marketing)、运输(transportation)和仓库(warehouse)。根据52种SCM数据源与这四种行为杠杆的关系,可以绘制出如下关系网络图(图2),从而帮助我们更好的理解不同数据源在整个供应链网络中的位置。

如此复杂的数据关系,如果不借助大数据分析的技术是无法将其转化为企业供应链可利用的价值的。现在的企业往往收集大量的数据却不知道如何利用(business collect more data than they know what to do with), 所以企业必须将数据不再看成信息资产而是战略资产,也就是说在所有企业都在努力收集这些供应链数据的大环境下,拥有大量数据已经不能成为企业绝对的竞争优势了;企业如何通过其独特的信息使用战略(大数据驱动的供应链管理)才是建立更有力的供应链竞争优势的途径。

图 2:点击查看大图

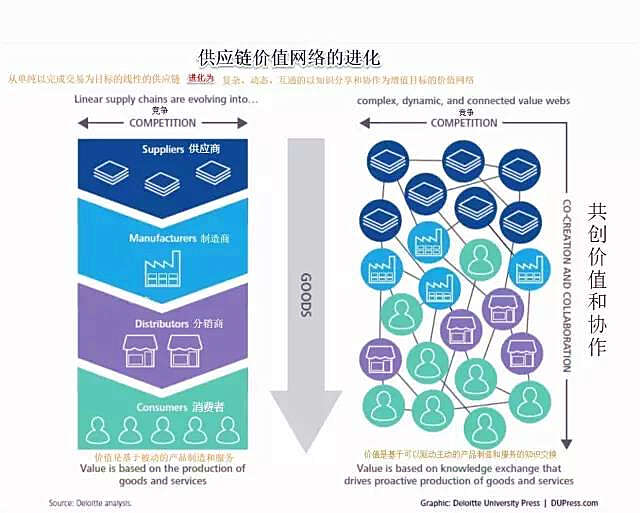

2、进化为知识共享型供应链价值网络

驱动更为复杂的专注于知识分享和协作的供应商网路,从而让供应商网络不仅仅是完成交易而是带来增值。

Enabling more complex supplier networks that focus on knowledge sharing and collaboration as the value-add over just completing transactions.

大数据正在变革供应商网络在新市场和成熟市场中形成、增长、扩张的方式。交易不再是唯一的目标,创建知识共享型的网络更为重要。从下图(图3)中可以看到供应链价值网络如何逐步向知识共享型进化。

Big data is revolutionizing how supplier networks form, grow, proliferate into new markets and mature over time. Transactions aren’t the only goal, creating knowledge-sharing networks is, based on the insights gained from big data analytics. The following graphic from Business Ecosystems Come Of Age (Deloitte University Press) (free, no opt-in) illustrates the progression of supply chains from networks or webs, where knowledge sharing becomes a priority.

图 3:点击查看大图

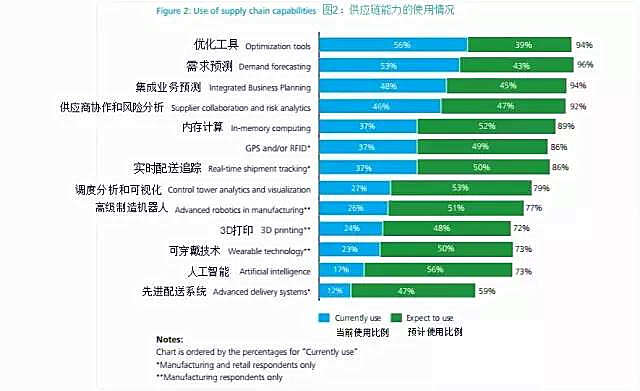

3、供应链能力的提升

大数据和高级分析技术正更快速的集成到供应链能力(Supply Chain Capabilities)当中。

Big data and advanced analytics are being integrated into optimization tools, demand forecasting, integrated business planning and supplier collaboration & risk analytics at a quickening pace.

德勤的调研显示,当前使用最多的前四种供应链能力为:优化工具,需求预测,集成业务预测、供应商协作和风险分析。更多见图4.

These are the top four supply chain capabilities that Delotte found are currently in use form their recent study, Supply Chain Talent of the Future Findings from the 3rdAnnual Supply Chain Survey (free, no opt-in). Control tower analytics and visualization are also on the roadmaps of supply chain teams currently running big data pilots.

图 4:点击查看大图

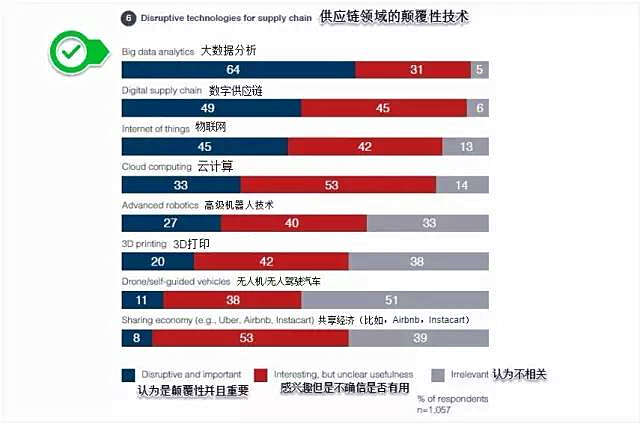

4、供应链领域的颠覆性技术

64%的供应链高管将大数据分析看成颠覆性的重要技术,这是企业长期变革管理的重要基础。

64% of supply chain executives consider big data analytics a disruptive and important technology, setting the foundation for long-term change management in their organizations.

图 5:点击查看大图

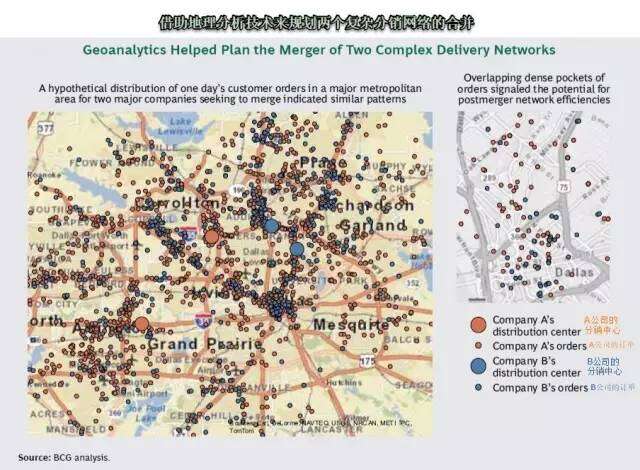

5、优化整合供应链配送网络

利用基于大数据的地理分析技术 (Geoanalytics) 来整合优化供应链配送网络。

Using geoanalytics based on big data to merge and optimize delivery networks.

波士顿咨询公司在文章“大数据如何在供应链管理中有效的应用”中解释了大数据是如何在供应链管理中应用的。其中一个案例解释了如何利用地理分析技术(Geoanalytics)规划两个供应链网络的优化和合并,见下图6:通过结合地理分析技术和大数据技术解决了这一领域中最大的服务问题 – 极大的减少了有线TV技术的等待时间同时提升了服务精准性。

The Boston Consulting Group provides insights into how big data is being put to use in supply chain management in the article Making Big Data Work: Supply Chain Management (free, opt-in). One of the examples provided is how the merger of two delivery networks was orchestrated and optimized using geoanalytics. The following graphic is from the article. Combining geoanalytics and big data sets could drastically reduce cable TV tech wait times and driving up service accuracy, fixing one of the most well-known service challenges of companies in that business.

图 6:点击查看大图

6、供应链问题的优化

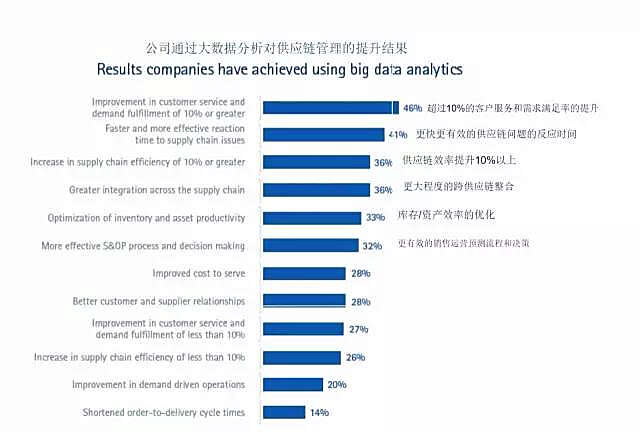

对供应链问题的优化。大数据可以帮助企业将对供应链问题的反应时间提升41%,将供应链效率提升10%甚至超过36%,跨供应链的整合提升至36%。

Big data is having an impact on organizations’ reaction time to supply chain issues (41%), increased supply chain efficiency of 10% or greater (36%), and greater integration across the supply chain (36%).The Big Data Analytics in Supply Chain: Hype or Here to Stay? Accenture Global Operations Megatrends Study found that companies are achieving significant results using big data analytics to improve supply chain performance and gain greater contextual intelligence.

图 7:点击查看大图

7、供应链运营的整合

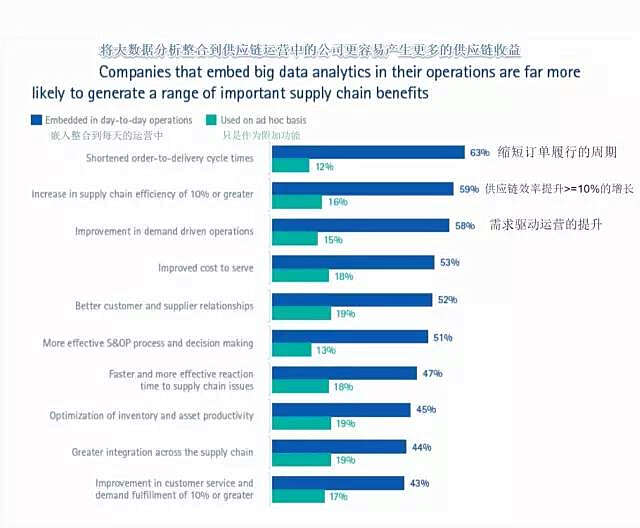

将大数据分析集成到供应链运营中可以将订单满足周期提升4.25倍、将供应链效率的提升2.6倍

Embedding big data analytics in operations leads to a 4.25x improvement in order-to-cycle delivery times, and a 2.6x improvement in supply chain efficiency of 10% or greater. Accenture found that embedding big data into supply chain operations accelerates supply chain processes a minimum of 1.3x over using big data on an ad hoc basis.

Source: Big Data Analytics in Supply Chain: Hype or Here to Stay? Accenture Global Operations Megatrends Study

图 8:点击查看大图

8、供应链财务指标的追踪

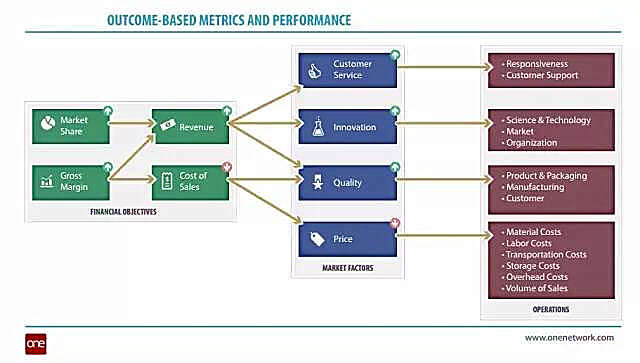

对供应链战略、战术、运营更深入的情境智能应用,正在影响公司的财务指标。

Greater contextual intelligence of how supply chain tactics, strategies and operations are influencing financial objectives.

供应链可视化,通常是指能够清晰的看到供应链网络中供应商的多层次结构。作者的经验告诉我们,通过供应链决策的财务结果追踪回财务指标是可行的;而且通过将大数据应用与财务系统集成,提升行业快速的库存周转率是非常有效的。

Supply chain visibility often refers to being able to see multiple supplier layers deep into a supply network. It’s been my experience that being able to track financial outcomes of supply chain decisions back to financial objectives is attainable, and with big data app integration to financial systems, very effective in industries with rapid inventory turns. Source: Turn Big Data Into Big Visibility.

图 9:点击查看大图

9、产品质量追踪

产品追踪和召回本质上都是数据密集型的,大数据在这方面的潜在贡献是显著的。

Traceability and recalls are by nature data-intensive, making big data’s contribution potentially significant. Big data has the potential to provide improved traceability performance and reduce the thousands of hours lost just trying to access, integrate and manage product databases that provide data on where products are in the field needing to be recalled or retrofitted.

10、供应商质量提升

通过基于大数据的质量控制可以提升供应质量。

Increasing supplier quality from supplier audit to inbound inspection and final assembly with big data. IBM has developed a quality early-warning system that detects and then defines a prioritization framework that isolates quality problem faster than more traditional methods, including Statistical Process Control (SPC). The early-warning system is deployed upstream of suppliers and extends out to products in the field.

本文原文作者:Louis Columbus, Fobes专栏作家

I’m serving as Director of Marketing, eCommerce and Analytics for Apttus. Previous positions include product marketing at iBASEt, Plex Systems, senior analyst at AMR Research (now Gartner), marketing and business development at Cincom Systems, Ingram Micro, a SaaS start-up and at hardware companies. I am also a member of the Enterprise Irregulars. My background includes marketing, product management, sales and industry analyst roles in the enterprise software and IT industries. My academic background includes an MBA from Pepperdine University and completion of the Strategic Marketing Management Program at the Stanford University Graduate School of Business. I teach MBA courses in international business, global competitive strategies, international market research, and capstone courses in strategic planning and market research. I’ve taught at California State University, Fullerton: University of California, Irvine; Marymount University, and Webster University. You can reach me on Twitter at @LouisColumbus. The author is a Forbes contributor. The opinions expressed are those of the writer.

更多阅读: